Service > Service Details

Integrity Test

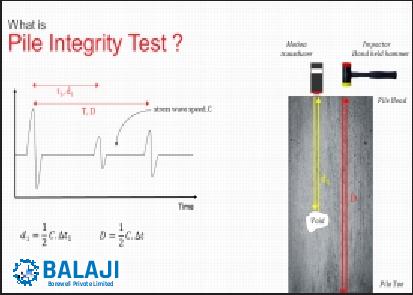

A pile integrity test (also known as low strain dynamic test, sonic echo test, and low strain integrity test) is one of the methods for assessing the condition of piles or shafts. It is cost effective and not very time consuming. Pile integrity testing using low strain tests such as the TDR (Transient Dynamic Response) method, is a rapid way of assessing the continuity and integrity of concrete piled foundations. The test measures: Pile length, or depth to anomalies Pile head stiffness Pile shaft mobility – which is dependent on pile section and concrete properties The software also produces computer simulations and impedance profiles of the test result, to analyse in detail any intermediate pile shaft responses. The TDR test requires minimal of preparation and is able to find defects corresponding to cracks, reductions in section and zones of poor quality concrete The test is based on wave propagation theory. The name “low strain dynamic test” stems from the fact that when a light impact is applied to a pile it produces a low strain. The impact produces a compression wave that travels down the pile at a constant wave speed (similarly to what happens in high strain dynamic testing). Changes in cross sectional area – such as a reduction in diameter – or material – such as a void in concrete – produce wave reflections. This procedure is performed with a hand held hammer to generate an impact, an accelerometer or geophone placed on top of the pile to be tested to measure the response to the hammer impact, and a data acquisition and interpretation electronic instrument. The test works well in concrete or timber foundations that are not excessively slender. Usually the method is applied to recently constructed piles that are not yet connected to a structure. However, this method is also used to test the integrity and to determine the length of piles embedded in structures.

How to perform pile integrity test

The pile head surface should be accessible, above water, and clean of loose concrete, soil or other foreign materials. Any type of contamination should be removed (using a grinder) to reach sound concrete surface. This step is so vital, because the sensor and concrete should in firm contact. The location of the sensor should be away from the edges of the pile. The integrity testing should be performed no sooner than 7 days after casting of concrete. A hammer is used for impacting pile top. Motion transducer should be capable of detecting and recording the reflected echos over the pile top. Acceleration, velocity, or displacement transducers can be used for this purpose. The distance between the impact location and the sensor should be no larger than 300 mm. Several impacts are applied to the top of the pile. The reflected echos are then recorded for each individual impact. The primary shock wave which travels down the length of the pile is reflected from the toe by change in density between the concrete and the subsoil. However, if the pile has any defects or discontinuities within its length these will set up secondary reflections which will be added to the return signal.