Service > Service Details

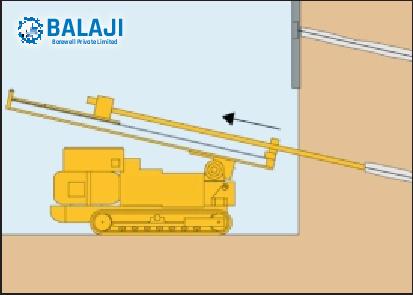

Ground Anchors

Ground anchors consisting of cables or rods connected to a bearing plate are often used for the stabilization of steep slopes or slopes consisting of softer soils, as well as the enhancement of embankment or foundation soil capacity, or to prevent excessive erosion and landslides. The use of steel ground anchors is often constrained by overall durability in placement (due to weight), and the difficulty in maintaining tension levels in the anchor. Anchor systems fabricated from fiber reinforced composite materials show a number of benefits compared to conventional systems for the following reasons: Enhanced durability including resistance to corrosion and resistance to alkalis and solutions in soils increase their life and greatly reduce the need for maintenance, thereby decreasing lifecycle costs. Lighter weight results in easier transportation of cables to site, and increases the efficiency of handling and placement. Enhanced tensile strength coupled with lighter weight and enhanced mechanical properties results in greater safety during installation in areas with limited clearance. In most cases, it is possible to use conventional jacking systems and still realize greater flexibility in placement and tensioning in difficult ground formations. Composite ground anchors generically consist of three parts: The anchorage is generally a stainless steel sheath with an anchor nut/plate through which the composite cable is run. The anchorage is usually filled with a non-shrink expansive cement mortar that ensures fixity and no slippage. The anchorage also is used to fasten the system to the outside structure. The cable can consist of multiple rods that are separate or braided together, or a single rod. A sheath or sleeve made from polyethylene or PVC that is fitted around the free anchor length of the cables.